...

When we make our jackets, we want to give you as much insight into the creative process as possible. Whether it's how our fabrics are made, the details we add or take away, or how we do our photoshoots. For Batch No.2, we wanted to push it a step further and show you exactly what we're doing to bring our jackets into the world. Batch Notes covers every step before we sold out in October 2019, and beyond, behind the scenes of the making process.

So, here it is, a play by play of Batch No.2 in the making.

...

Sept '18

On a 48 hour trip to Paris we found a vintage moleskin chore jacket which had worn beautifully over the years. It must have been 60+ years old and still going. After some digging, we find out the fabric was made in France. Our fabric hunt began.

...

Sept '18

We contacted all the mills we could find that make moleskin, but everyone said they’d moved production abroad. We found other mills in Europe, but the fabrics were too velvety. It reminded Huw of a pillow that his sister had when she was younger. When you brushed your hand one way, the colour of the pillow would change. Brushed it back, and the colour changed again. Not what we were looking for. The search continued.

...

May '19

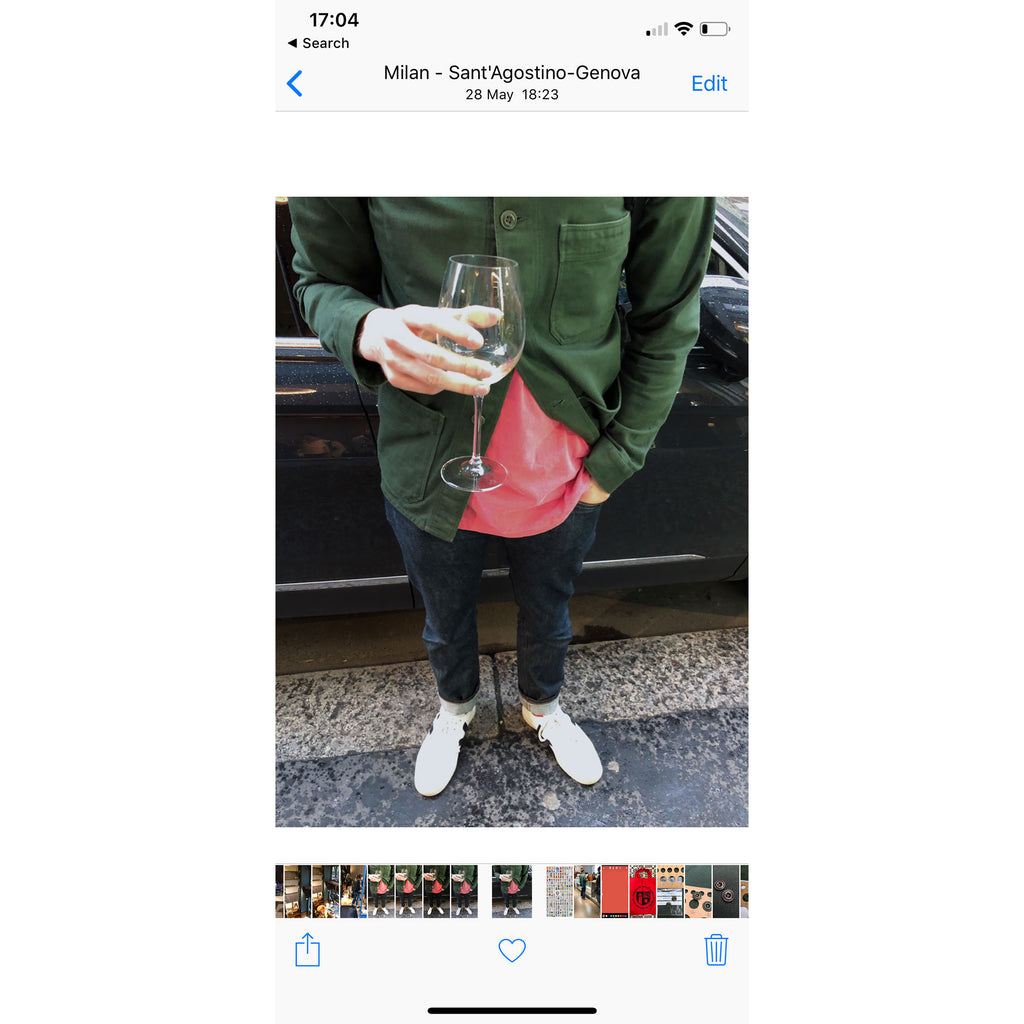

We go to Milan for a fabric trade show and look through hundreds of fabrics made by dozens of mills from all over the world. We stumble across a new mill and went through their entire collection. There it was. A stunning moleskin swatch. It’s beautiful. It’s woven densely to make it tough and long lasting. It has a shaved surface that looks and feels luxurious. Almost like suede. It’s just like the moleskin of the jacket we found in Paris last year. But, here’s the biggie: is it actually made in France? Yes, fully. One of the last of it’s kind. It’s go time.

...

May '19

We designed this jacket to be a cross between the traditional French chore jacket and the American chore jacket. The fit of the French, and the detailing of the American. The steel worker's chore jackets had buttons made from metal. We start sampling buttons by YKK, we wanted ours to be logoless.

...

May '19

As soon as we land in London our swatches of the moleskin arrive. We both love it, and we order 20m for sampling, sent to Sergio in Portugal. Sergio receives the sample meters and runs a shrinkage test.

...

May ‘19

Sergio receives the sample meters and runs shrinkage tests on the fabrics.

...

June '19

We finish the design of our jacket and send a tech pack to the factory to make our first sample. A tech pack is like an Ikea instruction manual for how we’d like our jacket to be made.

...

June '19

Our illustrator for Batch No.2’s label has been briefed. We can’t believe our luck. We remember finding his work when we were first texting. We’re so excited to be working with Hiller Goodspeed.

...

June '19

We decide to test two types of buttons for the jacket. One screw on, one fixed. Both beauties.

...

June '19

We fly over to Porto and take a bus north to Guimarães to have a meeting with the factory, to go over the new designs and colour scheme. Sergio likes it gives us the nod. We also nip onto the factory floor to see all the Batch No. 1 jackets being made.

...

June ‘19

Our illustrator has sent 4 options for the Batch No.2 label. We reply immediately, option D.

...

July ‘19

Becky goes full time on Paynter. Gulp.

...

July ‘19

Our pattern maker, Sandra, makes a new jacket pattern for Batch 2.

...

July '19

A sample jacket is cut in the moleskin fabric and it goes into production. The factory are in sampling mode, so it should take a couple of weeks.

...

July ‘19

Batch No.2 limited edition label signed off. We CAN NOT WAIT to show you.

...

July ‘19

Sergio sends our moleskin swatches to the dye house to get lab dips of our colour scheme. Every fabric reacts differently to dye, so you have to test every fabric with every colour. Except for black. Black is black.

...

July '19

The sample has been made, it’s off to be dyed. Very few brands garment dye moleskin. We can’t wait to see the result. We’re hoping for a matte, washed, worn-in look and feel.

...

July '19

Sergio gets the first sample of our new limited edition label. He also gets the lab dips back from the dye house and send us the swatches to pick which colours we’d like to go with.

...

July '19

Photoshoot planning begins. We scrapbook our ideas and start to build our mood boards.

...

Aug ‘19

Location scouting for Batch 2 photoshoot in North Wales. We chose one main location, and a couple of extra locations for some lifestyle shots.

...

Aug ‘19

A few What’sApp messages sent, and our friends are in for the Batch 2 shoot. Legends.

...

Aug '19

After a week of back and forth discussions and looking at the swatches in every kind of light and from every angle, we choose the final four colours for Batch 2.

...

Aug ‘19

Date set for Batch 2 launch. We're aiming for October 5th. Eek.

...

Aug '19

Call with photographer, Jim Marsden. We share our ideas for the shoot and he agrees to photograph Batch 2. Yay. The same day Sergio posts us the Batch No.2 sample via UPS next day.

...

Aug '19

Sample arrives at work. But we're working from home whilst the car is in the garage. As soon as the car is fixed we drive 90 miles to pick up the sample. We drive to the car park of a local leisure centre and open the package. We fall in love again. Huw puts it on. It will not come off for the next two months.

...

Aug ‘19

After a few days of wear we send first Batch 2 jacket feedback to Sergio. The changes will be worked on over the next week.

...

Aug ‘ 19

French moleskin fabric for Batch No.2 is ordered and paid for.

...

Aug ‘19

Photoshoot deck sent to Jim. He likes what he sees. We’re all excited.

...

Aug ‘19

One last tweak made to the jacket pocket detail before the photoshoot samples are made.

...

Aug '19

Meet up with models (friends) for lunch and chat about the shoot. We're lucky to have such great friends who want to get involved with the shoot.

...

Aug '19

Factory closes for two weeks. Sergio and the team get a well deserved summer break.

...

Aug '19

Jim buys the film for the photoshoot and stores it in his fridge.

...

Aug '19

It's the bank holiday weekend so we're having a break for a few days. We're heading up to North Wales for our friend Jess' birthday, and for a bit of chill time while the factory is resting too. Happy birthday Jess.

Aug '19

Next week our factory re-opens and work will begin on our jackets for the photoshoot. We have two models, an XS and an L. So we've ordered 8 jackets, four in each colour and each size.

Aug '19

Our mill is open again after the summer holidays and we've 'upgraded' our order to 100% BCI cotton which is a little extra per meter and entirely worth it to ensure the right quality and ethics. You can find out more about BCI here.

...

Sept '19

We made some very slight alterations to the shape of the pocket flap, here is the final shape. Sergio sent us a quick snap before the first samples go to the dye house.

...

Sept '19

8 samples are being dyed this week, the first week of September. They will arrive with us in 1 week's time, ahead of the photoshoot.

...

Sept '19

Moodboards for the shoot are shared with our models, between us, we're gathering the clothes we need to style the jackets as we'd like to.

...

Sept '19

The shoot takes place and it's hands down one of the best weekends of our lives. We're lucky to have such good friends to shoot with.

...

Sept '19

With photos back, we crack on building the website, fueled with coffee and strawberry laces. Our fabric arrives in Portugal.

...

Sept '19

Our fabric has left France and arrived in Portugal. Our team have begun shrink-testing every roll of fabric individually. No roll un-tested. The factory is ready now. 1 week to go.

...

Oct '19

05.11.19. It’s go time.

3 minutes later, and we have sold out. Oh Woah. Thank you.

On the Monday after we sold out, we place our order on FaceTime with Sergio. A face to face meeting is better than a thousand emails. Sergio and his team pass on their thanks. The same week, our fabric that had been 10 weeks in the making arrives from Alsace, France. Each roll was sent 20km up the road to Agostinho's dye house.

First, we tested each roll of fabric for shrinkage, to make sure the pattern is calculated exactly to the right dimensions. Jackets naturally shrink a little when they are dyed, so we increase our measurements to accommodate. Then, they won't shrink again.

Next, cutting begins. Once the pattern has been adjusted for natural shrinkage, Sandra in the pattern room calculates how to make each piece fit onto fabric laid out flat, making sure there's as little waste as possible. Then, each size is cut with scissors and a keen eye.

At every stage throughout the making process, jackets are being checked by Sergio, Lutz, and their team. To put it simply, they're ruthless. If there are any details less than perfect, they don't cut corners, they start all over again.

...

Nov '19

Sewing begins. First, we look after the details, such as hemming the inside of every pocket, before it's sewn on. It's also time for the zig-zag stitching underneath the collar.

Once the body is sewn together, it's time to add the arms, the limited edition label by Hiller Goodspeed and all of the pockets.

Our labels have to be sewn in before the pocket is attached to the main body, because they are stitched inside the pockets.

That means, labels are sewn in before the jackets are dyed.Our labels are dye resistant, so the bright red isn’t tainted from the dye process.

Now the jackets are fully sewn, they head up the road to the dye house for a seven hour dye treatment that gives each jacket a super soft feel.

With dying complete, they come back to our factory for a final quality check and to have their buttons attached.

And then comes the day when they leave Guimarães, to be sent to us. Our jackets travel by truck, we find it to be the best method of transport for us. It’s quicker than by boat, and it’s less harmful than by air.

When they arrive. We'll celebrate. Then, get to work checking every detail again, and again. Then package up, one by one, to head off around the world.

...

Dec '19

Over to you.

...